Shaftless Spiral Design Magnetic Separation Machine for Conveying

of Viscous and Agglomerated Materials

Spiral Conveyor Function

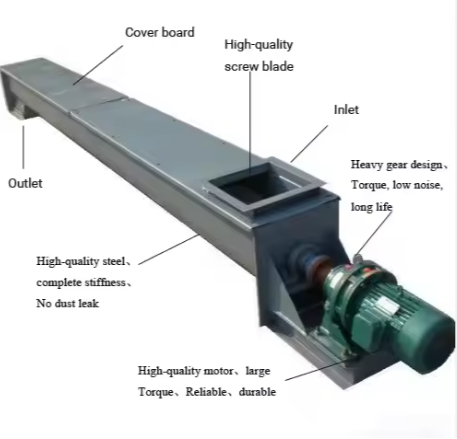

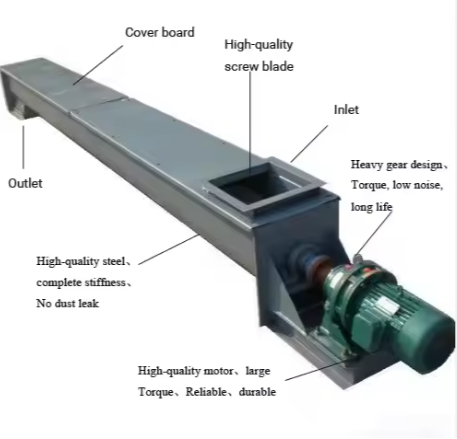

The screw conveyor utilizes a rotating screw to move conveyed

materials within a fixed casing. The head and tail bearings are

moved into the housing, and the hanger bearings employ sleeve

bearings with dust-proof sealing devices. The bearing bushings are

typically made of powder metallurgy, while felt liners are used for

conveying concrete. The hanger shaft and screw shaft are connected

through sliding blocks.Shaftless Spiral Design: The unique shaftless structure effectively

avoids entanglement and clogging of powdered materials, especially

suitable for viscous and easily agglomerated materials such as

sludge, flour, and chemical powders. It ensures smooth and

efficient material conveying.

High-quality Stainless Steel Material: Made of 304/316 stainless

steel, it is corrosion-resistant, easy to clean, and fully complies

with food-grade and chemical hygiene standards. For special needs,

mirror polishing treatment or high-temperature/acid-alkali

resistant coatings can be selected to further enhance the

equipment's lifespan and performance.

Fully Enclosed Leak-proof Design: The fully enclosed trough design

effectively prevents dust spillage, meeting environmental

protection requirements and ensuring a clean and safe working

environment.

Anti-static/Explosion-proof Configuration: Customized anti-static

or explosion-proof configurations are provided for flammable and

explosive powdered materials to ensure safe production.

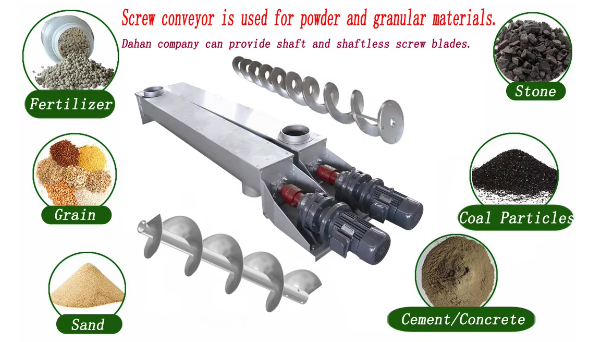

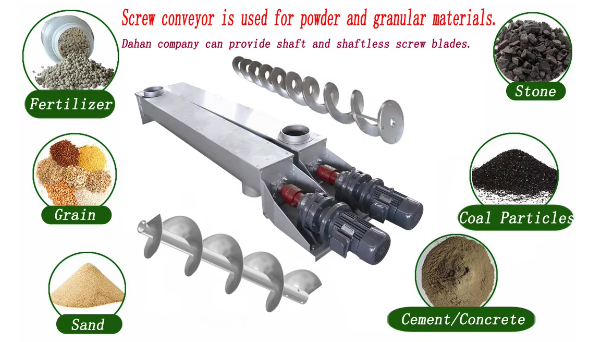

Spiral Conveyor Application

1. Food Industry: Suitable for conveying flour, sugar powder,

additives, etc. Requires the use of 304/316 stainless steel and

food-grade lubricants to ensure product hygiene and safety.

2. Environmental Protection Industry: Suitable for conveying

sludge, biomass particles, etc. Can be paired with wear-resistant

linings to improve equipment durability.

3. Chemical Plants: Suitable for conveying carbon powder, plastic

particles, catalysts, etc. Requires explosion-proof motors and

nitrogen protection systems to ensure safe and stable production.

4.Made of stainless steel 304, with strong corrosion and heat

resistance.

5.Disassemblable design for easy routine maintenance and component

replacement,Variable speed motor can adjust rotation speed according to

material characteristics and conveying needs

Spiral Conveyor Technical Parameters

| Attribute Category | Detailed Information |

|---|

| Basic Information | |

| Product Name | Screw Conveyor |

| Brand | Customized (Custom Brand) |

| Dimensions & Appearance | |

| Dimensions (L×W×H) | Please provide specific dimensions for customization |

| Product Characteristics | |

| Specialty | Highly durable, suitable for long-term continuous operation |

| Material | Stainless Steel 304 (with thermal insulation properties) |

| Strapping Material | Carbon Steel |

| Technical Parameters | |

| Rotation Speed | 1500 RPM (Revolutions Per Minute) |

| Motor | Variable Speed Motor |

| Function | Positive Drive |

| Customization & Installation | |

| Special Type | Disassemblable design for easy maintenance and component

replacement |

| Installation Service | On-site installation guidance by experienced engineers |

| Applicable Industries & Applications | |

| Applications | Suitable for continuous conveying and transfer of powders and

granular materials |