U-shaped Horizontal Spiral Belt High-efficiency Powder Mixer

Powder Mixer Function

Efficient Mixing with Low Energy Consumption: The U-shaped

cylindrical structure and the design of positive and negative

rotating spiral belts ensure that materials move with low

resistance within the mixing chamber, while generating intense

convective and shear mixing effects, achieving efficient mixing

while reducing energy consumption.

High Uniformity with Low Breakage Rate: The spiral belt blades are

typically made in two or three layers. By utilizing spiral layers

in different directions to collect material from both sides to the

center or convey material from the center to both sides, more

vortices are created, accelerating mixing speed, improving mixing

uniformity, and minimizing damage to crystals.

Wide Applicability: Suitable for mixing powders with powders or

viscous materials, with the ability to introduce large amounts of

liquid into the materials during the mixing process, meeting the

mixing needs of various materials.

Powder Mixer Application

Pharmaceutical Industry: Used for mixing pharmaceutical raw

materials to ensure uniform drug composition and improve drug

quality.

Food Industry: Mixed various powdered ingredients in food

production, such as flour, sugar, milk powder, as well as

seasonings and additives, to ensure food taste and quality.

Chemical Industry: Suitable for mixing various chemical raw

materials, such as zinc oxide, detergents, additives, calcium

carbonate, etc., to meet chemical production needs.

Construction Industry: Used for mixing mortar, gypsum, and other

building materials to improve their uniformity and strength.

Paint and Dye Industry: Mixed pigments and additives in paint and

dye production to ensure uniform color and improve product quality.

Powder Mixer Technical Parameter

| Attribute Category | Description/Specification |

|---|

| Product Name | U-shaped Horizontal Spiral Belt High-efficiency Powder Mixer |

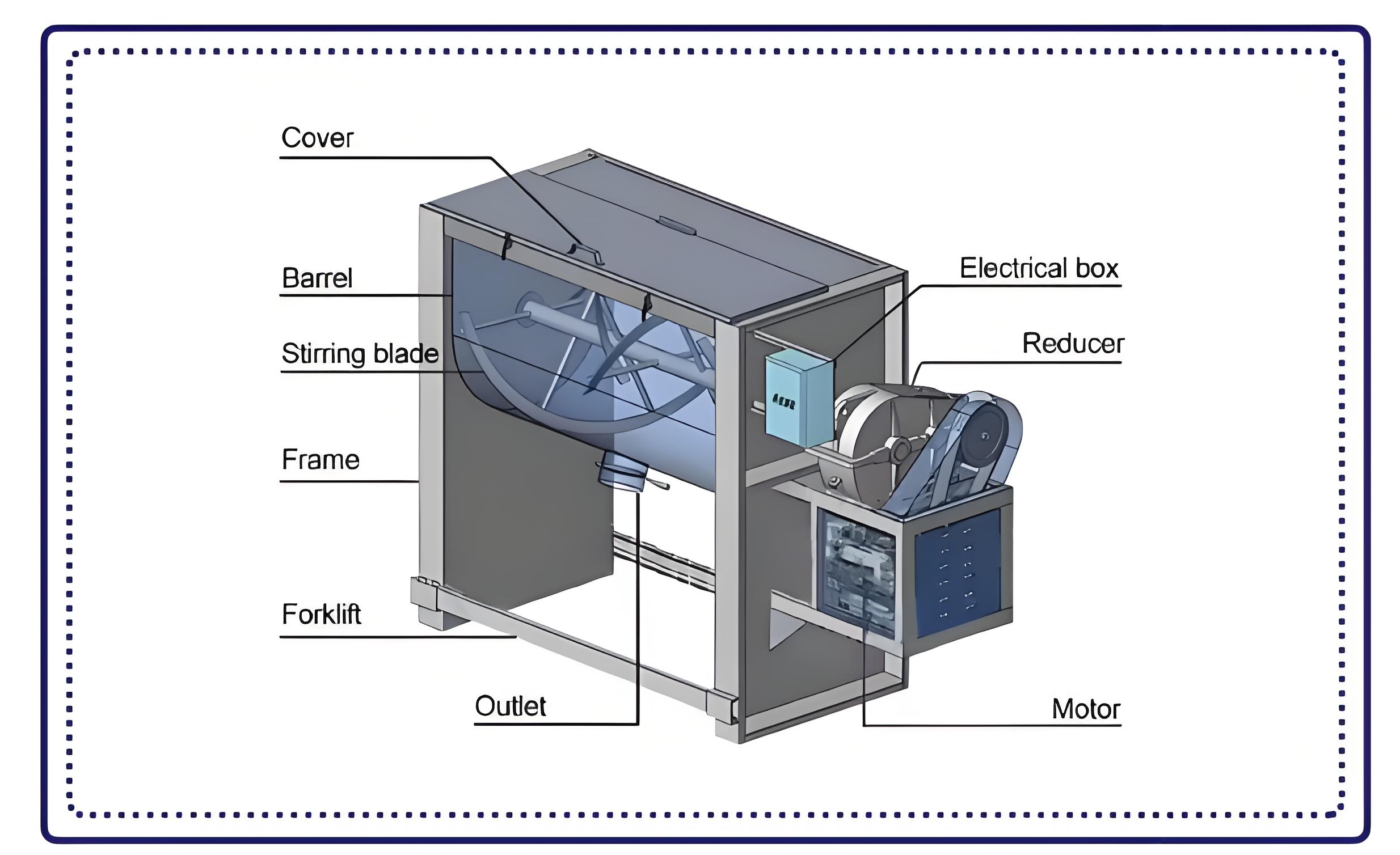

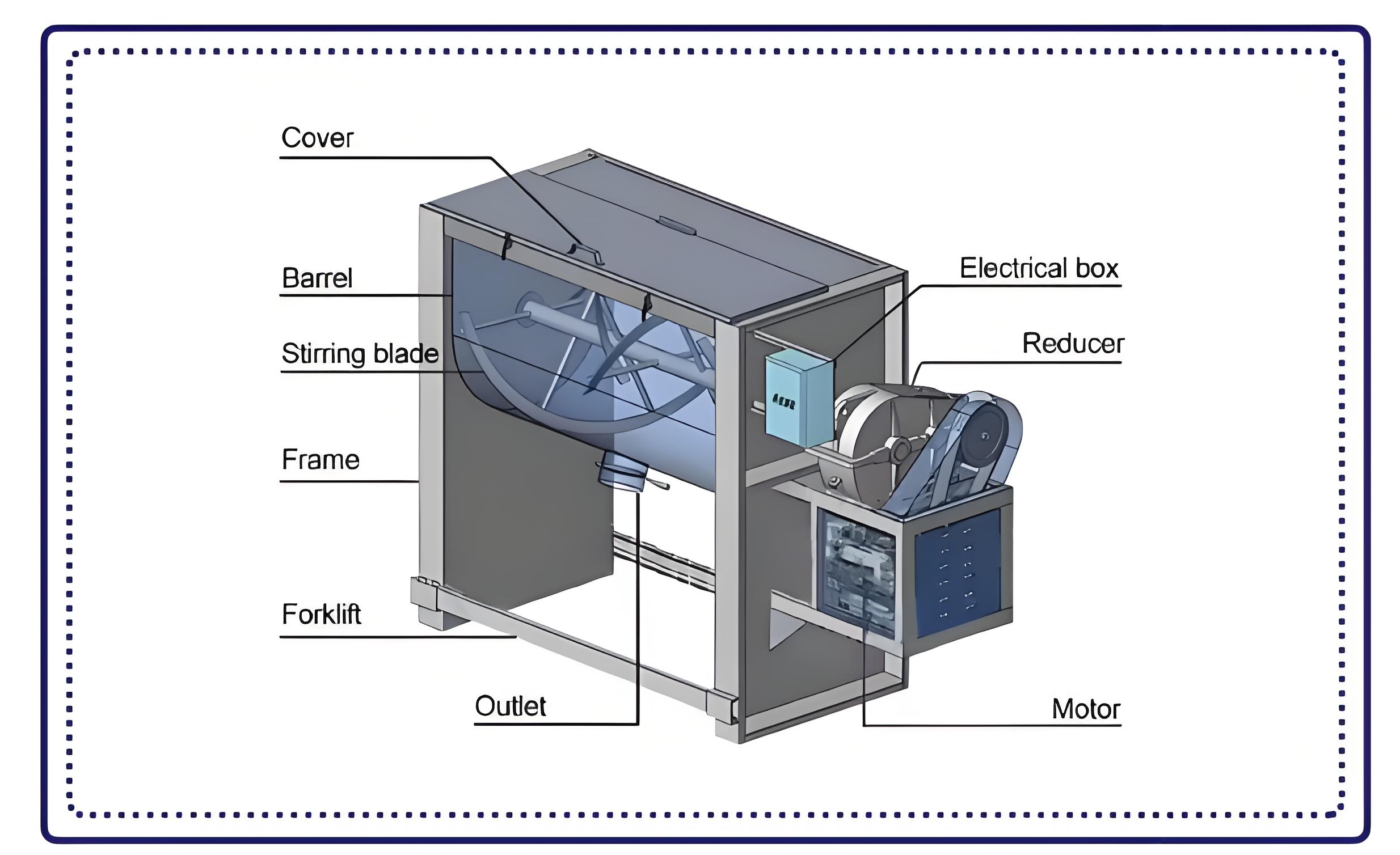

| Structural Form | U-shaped cylindrical body with continuous spiral belts inside |

| Drive Method | Driven by motor reducer, located on the end face of the equipment |

| Mixing Characteristics | Stable mixing with minimal crystal destruction; overall motion

state requiring high power; short mixing time |

| Material Adaptability | Mixing of powders with powders and viscous materials; capable of

incorporating large amounts of liquid |

| Material State | Solid powders, viscous substances |

| Spiral Belt Design | Inner and outer layers are left-hand and right-hand spirals

respectively; the inner layer is wider than the outer layer,

creating intense convective and shear mixing effects |

| Number of Blade Layers | Typically made in two or three layers |

| Mixing Effect | Generates vortices, accelerating mixing speed and improving mixing

uniformity |

| Energy Efficiency | Low power consumption, high efficiency |

| Loading Coefficient | High |

| Application Fields | Pharmaceutical, food, pesticide, chemical, construction, paint,

dye, feed, and many other industries |