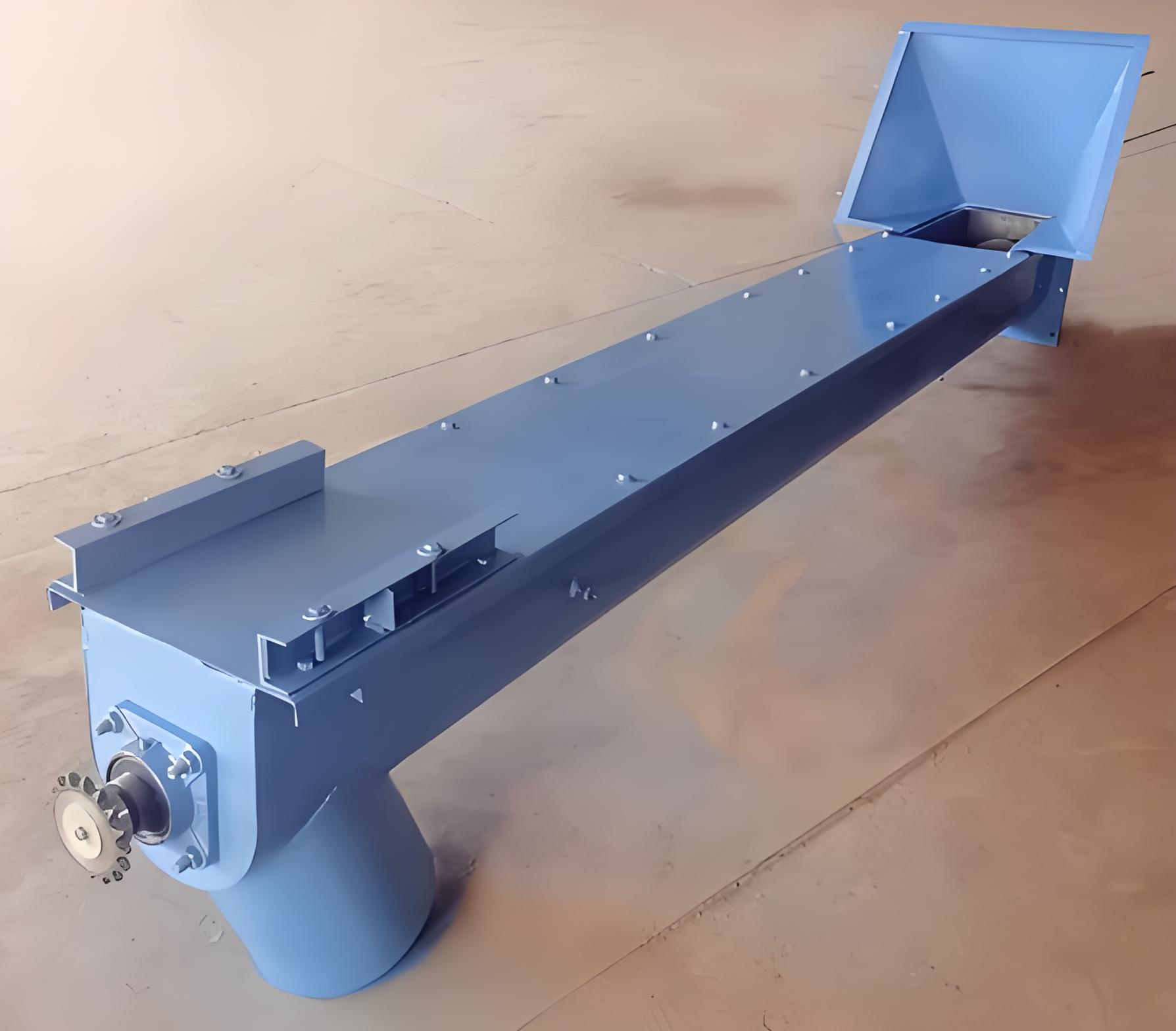

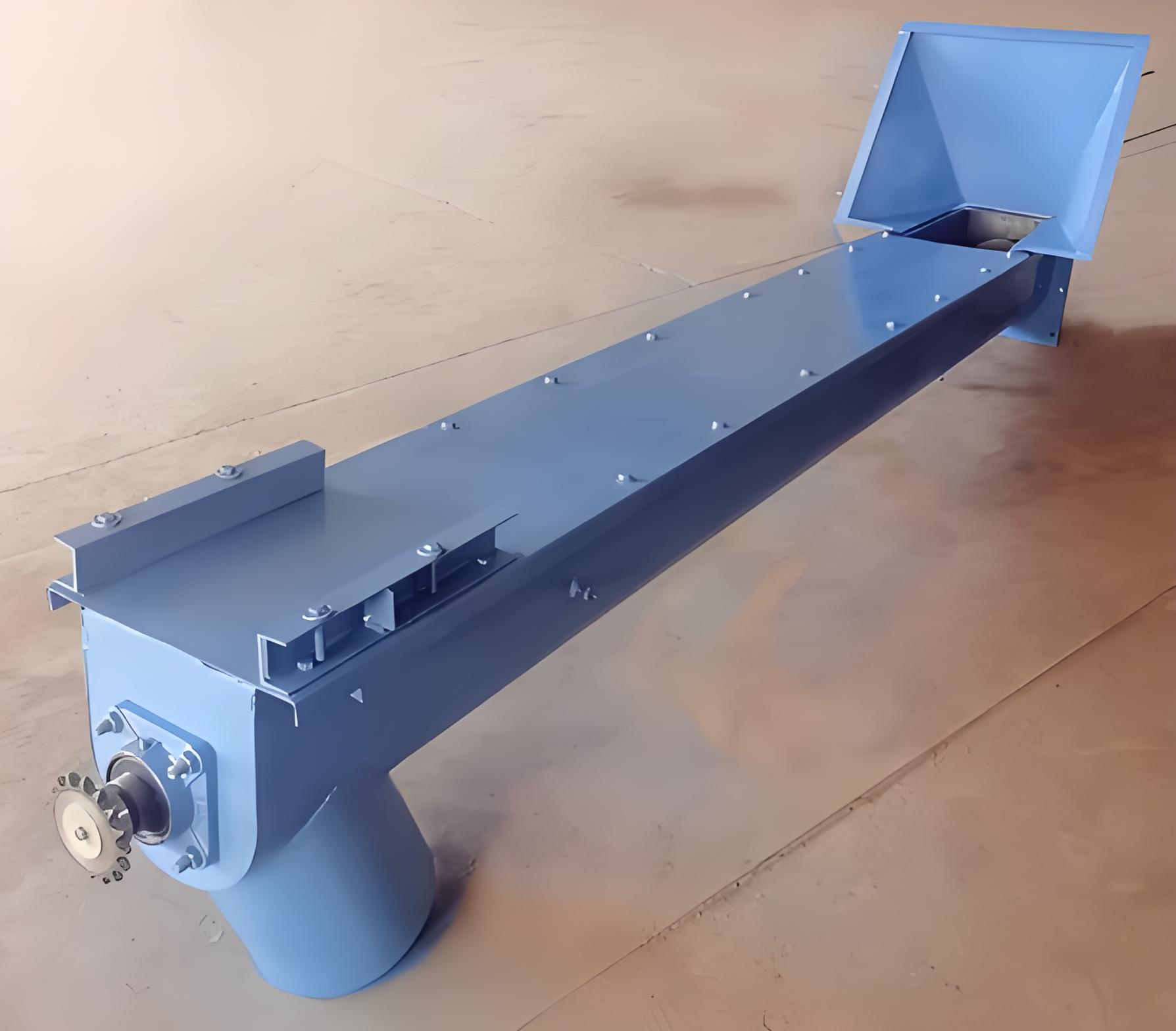

High-Temperature Stainless Steel Heavy-Duty U-Trough Auger Conveyor

for Hay or Straw Mixed with Milk Powder

Auger Conveyor Function

Clean and Environmentally Friendly Production:

Specifically designed for conveying dusty, hot, and pungent

materials, this conveyor ensures clean and environmentally friendly

production processes.

Enhanced Wear Resistance:

The wear-resistant treated screw is more durable and robust than

traditional screws, significantly extending its service life and

reducing maintenance costs.

Flexible Feeding and Discharging Options:

With the ability to accommodate multi-point feeding and discharging

based on user process layouts, this conveyor offers unparalleled

flexibility and convenience.

Auger Conveyor Application

1.Agricultural Processing:Ideal for conveying hay, straw, and other

agricultural byproducts mixed with milk powder in feed production

lines.

2.Food Processing:Suitable for handling dusty or odorous food

ingredients in food manufacturing plants.

3.Chemical Industry:Can be used for conveying granular or powdered

chemicals that require temperature control and cleanliness.

4.Biomass Energy:Perfect for transporting biomass materials like

straw or wood chips for energy production.

5.Waste Management:Useful in waste recycling plants for conveying

materials that are dusty, hot, or have pungent odors.

Auger Conveyor Technical Parameter

| Attribute Name | Description |

|---|

| Material | High-temperature stainless steel |

| Type | Heavy-duty U-trough auger conveyor |

| Suitable Materials | Hay, straw mixed with milk powder, etc. |

| Wear Resistance | Specially treated for wear resistance to enhance service life |

| Cleanliness & Environmental Friendliness | Designed for clean and environmentally friendly production,

suitable for dusty, hot, and pungent materials |

| Conveying Capacity | Customizable based on user requirements |

| Feeding/Discharging Method | Capable of multi-point feeding and discharging with optimized

discharging structure |

| Structural Characteristics | Compact structure with fewer vulnerable parts |

| Installation & Maintenance | Easy and quick installation, operation, and maintenance |

| Temperature Adaptability | Suitable for high-temperature environments |

| Safety | Complies with relevant safety standards and equipped with necessary

safety protection devices |

| Customization Service | Offers customization based on specific user needs |